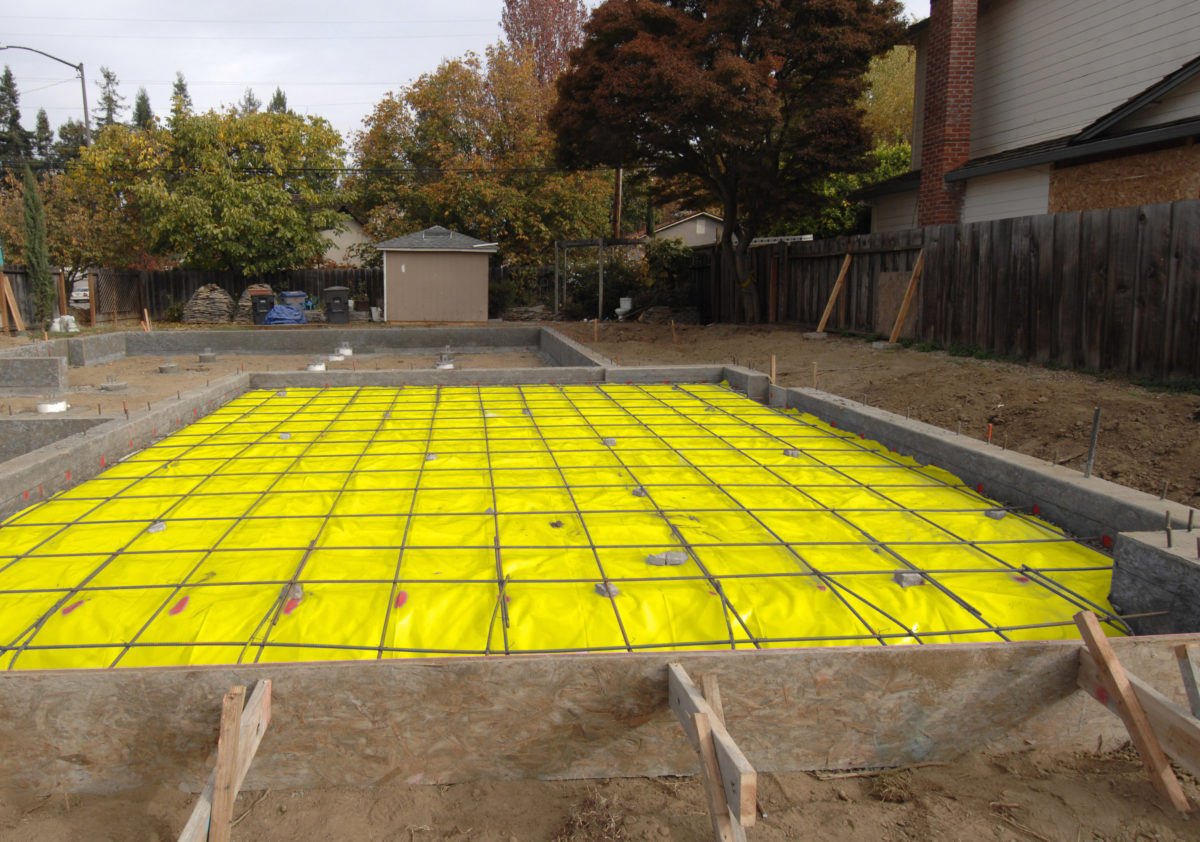

If you look closely, there is plastic under concrete slabs that is a thin membrane, mostly waterproof to minimize water vapor. Choosing the right vapor barrier and installing it correctly is an utmost priority for most property owners in Australia. Therefore, experts at Structural Consultancy have the knowledge and skills to give the best advice regarding it speaking from experience and vast training.

The Purpose of Concrete Vapor Barriers

It is often a misconception that installing vapor barriers is a direct source of waterproofing the concrete slabs of a building. However, waterproofing in itself is a subject of its own intricacies and is not achieved plainly by installing vapor barriers. Waterproofing requires different expertise as well.

On the other hand, a vapor barrier concrete is a plastic membrane beneath the slabs used in residential buildings, making it popular amongst homeowners in Australia. Moisture is a culprit in many problems that arise regarding flooring. Moisture entering the concrete slabs is a one-way process as it enters through the surface due to various reasons including humidity, plumbing that leaks, moisture from the soil, or water poured over the surface. It is essential for the concrete to dry up as soon as possible and to remain dry to avoid damage to the floor, as mainly seen in basement floors.

Therefore, the rise of this essential need has resulted in concrete vapor barriers which are a material added below the concrete slabs to minimize the entrance of moisture.

In the meantime, preventing the reverse effect from occurring is also a purpose of adding vapor barrier concrete. The moisture content in the concrete mix needs to stay intact to keep the concrete mix fine. Thus, there are chances of the dry ground soaking in water from the freshly poured concrete. Hence, again, the barrier comes in handy to reduce the transference of moisture from the concrete to the soil.

Read More: Structural Engineer in Brisbane

Additional Benefits of Vapor Barrier Concrete

Making such a huge investment with Structural Consultancy comes with more advantages to make it worthwhile. Not allowing moisture to degrade the concrete slabs, corrode them, and prevent damage to the floors is one thing. The other is safety from toxic gasses like radon and methane.

These gases naturally exist in the soil. However, prolonged exposure to these gases affects one’s health, raising problems like lung cancer. But, with vapor barriers, there is a certain amount of insulation from these gases as well, making the air cleaner for the residents to breathe.

The Difference Between a Vapor Barrier and Slab Underlayment

Vapor barriers are often confused with underlayment. Engineers at Structural Consultancy understand the difference given their knowledge and apply what’s appropriate as per the requirements and location of the house in Australia. Their experience in the country gives them the leverage to make informed decisions alongside their clients.

Nevertheless, underlayment is a layer of flooring between the subfloor and the finished floor. The main goal of it is to support the uppermost layer of flooring, next to preventing mold. It also helps reduce noise and add to insulation. Thus, some underlayments can simply act as vapor barriers but the two are not actually the same.

Possible Consequences of Not Installing Moisture Barrier Concrete

Structural Consultancy ensures that the aftermath is as less severe and apparent as it can get, keeping the client’s safety their top priority. Therefore, if it doesn’t do a good job at installing these vapor barriers, the possible results of increased moisture would be:

- Sealers will be delaminated.

- Aggregates may be damaged.

- The slab may begin to curl.

- The bonds in the overlay may fail.

- Acid stains may be discolored.

- The objects beneath the floor may begin to condense.

- Efflorescence on the surface may be produced.

Learn More: How To Find a Structural Engineer?

Hence, Structural Consultancy ensures that the installation is precise and accurate.

The Correct Installation of Vapor Barrier Concrete

To install a vapor barrier is not a free-hand concept. Rather, Structural Consultancy understands that the requirements of the vapor barrier Australian Standard are dictated by the NCC – the National Construction Code (Australia), as well as the Australian Standard AS2870 for Residential Footings and Slabs.

These policies, which our well-studied by engineers at Structural Consultancy, help determine whether adding a vapor barrier under concrete slabs is essential or not – what are the requirements that necessitate its installation?

Once that is determined, installation can begin. Typically, vapor barriers come in several thickness levels ranging from 6-20 millimeters. In this range, 6 millimeters is what is typically used for residential projects made with concrete. The ones between 10-20 millimeters are mostly recommended for commercial projects. Nonetheless, it all comes down to the requirements of the Australian Code.

So, if you’re looking for a vapor barrier to be placed under your concrete slab, Structural Consultancy will not only guide you through the process but will also give you a price quotation suitable to your budget. First, however, it’s always better to know whether or not you even need a vapor barrier to save your own time and energy later.

Checkout: Structural Engineer in Melbourne